Today we don't want to talk to you about parts, used or reconditioned, but about the 12 main checks we recommend when you are about to buy a used excavator.

WHAT WILL YOU USE IT FOR?

Before you decide what kind of used excavator to buy, you need to be clear about what you will use it for. This seems like an obvious consideration, but it really isn't!

Harder applications, such as quarry face digging, demolition, and rock excavation require used machines with not too many hours on them, well-maintained and equally well-checked before purchase.

Conversely, if you intend to use your used excavator for light earthmoving you can go for older machines.

AND HOW MUCH WILL YOU USE IT?

Another key parameter: how many hours a day does the excavator have to work? If it has to go on two shifts, we strongly recommend a new machine, while if you have to do production on one shift and continuous loading, forget about buying a used excavator with many hours. You risk a bloodshed with the machine always standing still and a line of angry truck drivers....

It’s different if you are looking for an accessory machine that will work a few hours a week, without the hassle of having to finish before you have started. Then you can opt for machines with more hours, perhaps even not in perfect working order.

Remember, however, that safety is always essential, especially when it comes to used machines. No discounts on this!

#6 STATIC CHECKS# to absolutely do to avoid surprises when you buy a used excavator.

The more precise you are in checking, the fewer problems you will have in the future, however, this six-step list is a must follow.

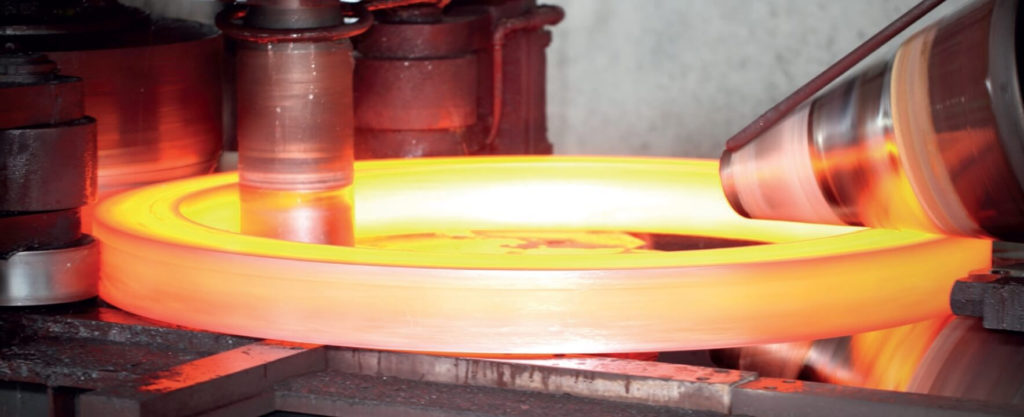

- The slewing ring should be checked carefully since it is one of the absolute most expensive parts to replace also because it requires a lot of labor; often, due to bad use (overloads) and poor and insufficient care in lubrication the slewing ring gets damaged. #TRUCK To check it? Rotate the turret 90° and check for play or instability in rotation.

- Also check the pins and bearings on the arm coupling and between the arm and forearm and between it and the fixture: they should be well tightened and not have too much play.

- Check for cracks or dents on the arm and forearm especially in the joint area. A cracked element will need to be replaced in the short term, especially if you will be using the excavator continuously. You should also look carefully for dents and other signs of wear throughout the excavator frame. Probably in most cases these will just be blemishes, but in some areas it could be a sign of something more serious. Lots of dents then are evidence of bad use of the machine (inexperienced or careless operators) and thus may suggest more obsolescence than is visible.

- Look for fluid leaks. For both the hydraulic and cooling systems, any used excavator can have leaks. In some cases they are not serious (loose seals or couplings) in others they may be a sign that something major is wrong. In the meantime that you are looking for leaks, collect a sample of hydraulic oil and have it analyzed by one of your trusted laboratories; you will be able to tell a lot from the analysis about the condition of the hydraulic system in general and, therefore, the actual value of the excavator.

- Are the hours right? If there is a trusting relationship with the seller, a look at the meter is enough; if, on the other hand, you feel that something doesn't add up, you can take a look at the foot pedals (if they look too worn compared to the hours officially worked).

- watch for scalloping (wear that occurs between the teeth of the bucket, in the shape of crescents)which indicates that the excavator has reduced penetration force. While this normally occurs over time and does not necessarily mean the bucket needs to be replaced, it is something to consider when assessing the overall value of the machine.

And then ... Try it out

It is essential to have a chance to try out the used excavator you intend to buy. Certainly visual evaluations and analysis can lend a sturdy hand, but there is nothing like a classic test drive to see if it is the machine for you.

The best would be to try it out in digging conditions, but very often this possibility is not there and you will have to be content to settle for turning it on the vendor's yard and doing a few motion tests.

But don't worry, even in this case, you can glean a lot of useful information!

Here are SIX dynamic CHECKS that are ESSENTIAL in evaluating a used excavator

- Check for play on the booms during movement

- Check the behavior of the machine under stress (in case you can dig)

- Listen to the engine! Irregular noises, excessive smoke presentation, discontinuity in power delivery are risk factors to consider

- Get it moving! Make a traverse of at least 50 meters and check the operating condition and digging response at the end of the traverse In the case of recent excavators, check the response to simultaneous and heavy-duty controls; it will tell you a lot about the state of the hydraulic system and the calibration of the electronics

- When the controls are electrohydraulic, check for leaks in the cab

- Check the cooling fan for proper operation and, in general, check the leaks in the cooling system